Introduction of SMD LED: What is SMD LED?

The light-emitting diode (LED) is a semiconductor device producing light. The illumination is emitted when the electrons carry the current passing through LED, and the performance of LEDs is better than other light sources with no doubts. In order to increase the manufacturing automation and to protect chips of LEDs, LEDs can be mounted directly onto the surface of printed circuit board (PCB), which is known as SMD LED.

Table of contents

What is SMD LED?

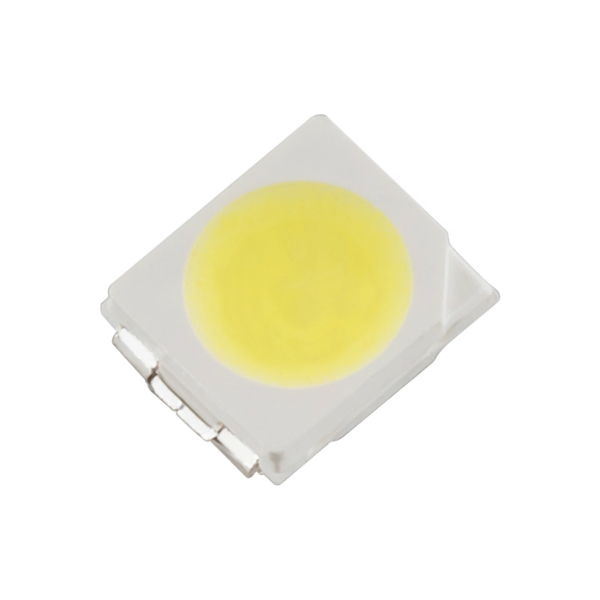

A surface mounted device LED (SMD LED) is LED mounted on the PCB without using wires by the manner of surface-mount technology (SMT). A SMD LED is a solid-state semiconductor device that converts electricity into illumination directly. One SMD LED is composed of five materials, including bracket, solid die bond, LED chip, gold wire, and epoxy.

A SMD LED is known for its parallelepiped shape, which is called LED chip. The colors of the LED chips are yellow and orange, generating warm or cold white lights. The chip of SMD LED contains the emitting areas inside, and the whole SMD LED chip is packaged with epoxy resin or silicone.

On the other hand, the core of the SMD LED is a semiconductor chip that is fixed on the bracket. One end of the bracket is the negative electrode, and the other end is connected to the positive electrode of the power supply.

Figure 1: SMD LED

In addition, the size of the SMD LED has the greatest influence on the brightness and power consumption of the lighting device. The larger the device, the higher the brightness level.

What is the Difference between COB LED and SMD LED?

According to the difference of LED chip packages, there are various types of LEDs, including SMD LED and COB LED.

COB LED

The chip on board LED(COB LED) is a new technology of light-emitting components. A COB LED comes as a high-powered chip that is wired on a PCB with optimal thermal management. Since there is no need for electroplating and reflow soldering, a COB LED takes up very little space after packaging. The closer arrangement and combination makes COB LEDs look more like a whole piece of emitting panel.

A COB LED allows a higher packing density, and the technology enables the development of high-power diodes with a small light-emitting surface area. Therefore, the COB LEDs may optimize the efficiency of illumination.

SMD LED

SMD LEDs feature high brightness. Currently, the most common type of LED on the market is SMD LED. LEDs which use surface-mount technology have replaced the old technology of using lead wire during assembly. With SMT, more electronic devices can be installed in a small or narrow space efficiently. Also, the technology contributes to the automation assembly and welding of PCBs.

The improvement of COB LEDs has brought with it two significant merits. One advantage is that COB technology provides the possibility to miniaturize the luminaires and the light sources. The other advantage is COB LEDs allow precise control of the distribution of the light beam due to the absence of space between one LED module and another.

However, the limitation of COB technology is that the power rating of the luminaire needs to be installed, and it is possibly less than 50/70W. SMD LEDs are preferred in high power applications because they are more reliable and perform better than COB LEDs. Besides, SMD LEDs can be used in color changing light bulbs, while COB LEDs cannot. Hence, SMD LEDs still have a wider application range compared to COB LEDs.

What are the Advantages of SMD LED?

Compared with traditional LEDs, SMD LEDs are lighter, thinner, shorter and smaller. Therefore, there are four influential advantages of SMD LEDs:

- Miniaturization in Product Design: SMD LEDs save more space on the base-plate and have the capacity of using reduced components, which conforms to trends of product miniaturization.

- Reducing Waste of Time, Effort, and Cost: Due to LED SMDs’tiny sizes, both production cost and processing time are declined, which makes the manufacturing process of SMD LEDs more efficient.

- Longer Duration of Usage: SMD LEDs have a longer estimated lifespan, and it gives you more savings in maintenance costs.

- Various Applications: SMD LEDs are better for a variety of uses, since the smaller the bulbs of LEDs are, the more versatile the applications of LEDs can be.

In conclusion, the main features of SMD LEDs are high durability, low power consumption and high standards of reliability and safety.

What are the Applications of SMD LED?

The mass production of factories and the continuous innovations of semiconductors cause SMD LEDs to be commonly used in industries. Not only did the price of SMD LEDs drop substantially, but also the SMD LEDs featured higher endurance and lower energy consumption. Therefore, SMD LEDs are widely used in LED lightings, light bars, vehicles and personal electronic devices, etc. Besides, SMD LEDs are also used in tiny smart appliances, such as wearable devices and consumer electronics.

Figure 2: Applications of SMD LED

Why to Choose Oasistek?

Taiwan Oasis Technology Co., Ltd. (Oasistek) has long been dedicated to the production and R&D of semiconductors and Light Emitting Diodes (LED) components for more than 48 years. When determining models of LED SMD, it is necessary to choose the most appropriate product according to types, colors, sizes, and brightness of the product. Oasistek provides various sizes of SMD LEDs that can be used in general lighting and backlight module products. Here are several reasons to regard Oasistek’s SMD LED products as first option:

- Manufacturing Integration: Oasistek has a complete and scientific quality control system. Furthermore, the R&D team of Oasistek integrates optics, circuits, controls, and mechanisms to improve manufacturing quality.

- Customization: The customization including adjusting colors of beam and the surface of LED is available. Oasistek devotes our resources to meet different needs.

- Electronic Professional Manufacturing Service: Oasistek provides printing, assembly, testing and packaging of various electronic products with LED light sources. We offer OEM service to various electronic products with professional SMT technology.

- Worldwide Certification: Oasistek incorporates safety systems in every step of our manufacturing process. Besides, we have global certification to serve clients in both domestic and international markets.

SMD LED Products

|

Orientation |

Package |

Part Number |

Length x Width x Height |

Illumination Color/Wavelength |

Material |

Lens Color |

Viewing Angle 2θ½ |

|

Top View |

PLCC 3014 Package |

3.0mm × 1.35mm × 0.7mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

|

Top View |

PLCC 3030 Package |

3.0mm × 3.0mm × 0.6mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

|

Top View |

PLCC 3528 Package |

(Single Color) |

3.5mm × 2.8mm × 1.9mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Top View |

Dual Color (TO-3228) |

(Dual Color) |

3.5mm × 2.8mm × 1.9mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Top View |

Specific Color (TO-3228) |

(Specific Color) |

3.5mm × 2.8mm × 1.9mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Top View |

RGB Color (TO-3228) |

(RGB Color) |

3.5mm × 2.8mm × 1.9mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Top View |

PLCC 5050 Package |

(Top View) |

5.0mm × 5.0mm × 1.5mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Top View |

RGB Color |

(RGB Color) |

5.0mm × 5.0mm × 1.5mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Side View |

PLCC 3006 Package |

3.0mm × 0.6mm × 0.8mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

|

Side View |

PLCC 3806 Package |

(Side View) |

3.0mm × 0.6mm × 0.8mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

|

Side View |

PLCC 4508 Package |

4.5mm × 0.8mm × 1.25mm |

White / Optional Blue / 468 Pure Green / 525 Yellow Green / 572 Yellow / 590 Amber / 605 Red / 630 |

Blue / InGaN Pure Green / InGaN Yellow / AlGaLnP Amber / AlGaLnP Red / AlGaLnP |

Water Clear |

120 |

What is the Difference between 2835 and 5050 and 3528?

|

Part Number |

Wavelength λ(nm)Cx/Cy |

Emitting Color |

Color Temperature |

Forward Voltahe |

Test Condition |

Typ Luminous Flux |

CRI |

Viewing Angle 2θ½ |

|

TO-2835TWLQ (0.2W/60mA) |

0.43/0.40 ,0.37/0.37 ,0.32/0.33 |

Warm White / Neutral White / Cool White |

2600K-3500K / 3500K-5000K / 5000K-9500K |

2.8-3.4 | 60 |

24-27 |

70-80 |

120 |

|

TO-2835TWLQ (0.4W/120mA) |

0.43/0.40 ,0.37/0.37 ,0.32/0.33 |

Warm White / Neutral White / Cool White |

2600K-3500K / 3500K-5000K / 5000K-9500K |

2.8-3.4 | 120 |

42-47 |

70-80 |

120 |

|

TO-2835TWLQ (0.2W/60mA) |

0.43/0.40 ,0.37/0.37 ,0.32/0.33 |

Warm White / Neutral White / Cool White |

2600K-3500K / 3500K-5000K / 5000K-9500K |

2.8-3.4 | 150 |

46-53 |

70-80 |

120 |

|

TO-5050 (0.2W/60mA) |

0.43/0.40 ,0.37/0.37 ,0.32/0.33 |

Warm White / Neutral White / Cool White |

2600K-3500K / 3500K-5000K / 5000K-9500K |

2.8-3.4 | 60 |

22-26 |

70-80 |

120 |

|

Part Number |

Material |

Emitting Color |

Clip λ(nm) |

Lens Color |

TYP |

MAX |

MIN |

TYP |

Viewing Angle 2θ½ |

|

TO-3528 |

InGaN / AlGalnP GaAsp |

Blue / Pure Green / High Bright Green / High Bright Yellow / High Bright Amber / Orange / High Bright Orange / High Red |

468/ 525/ 572/ 592/ 605/ 621/ 623/ 630 |

Water Clear |

3.3/ 3.3/ 2.2/ 2.0/ 2.0/ 2.0/ 2.0/ 1.9 |

3.6/ 3.6/ 2.4/ 2.4/ 2.4/ 2.4/ 2.4/ 2.4 |

146/ 417/ 51/ 417/ 542/ 10.5/ 417/ 417 |

281/ 805/ 98/ 805/ 1046/ 20/ 805/ 667 |

120 |

|

TO-5050 |

InGaN / AlGalnP GaAsp |

Pure Green / High Bright Yellow / High Bright Amber / High Bright Orange / High Red |

525/ 590/ 605/ 623/ 630 |

Water Clear |

3.3/ 2.0/ 2.0/ 2.0/ 2.0/ 1.9 |

3.6/ 2.4/ 2.4/ 2.4/ 2.4 |

2015/ 917/ 417/ 917/ 419 |

2711/ 1466/ 805/ 1466/ 667 |

120 |

Oasistek provides a variety of LEDs with different specifications and applications. For more information about semiconductors and LED products, you can contact Oasistek and submit your questions. We will soon reply to you and do our best to fulfill your needs.